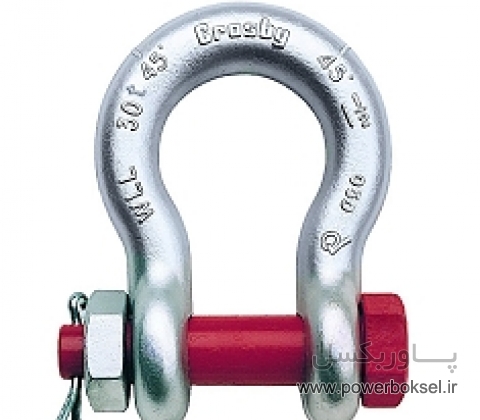

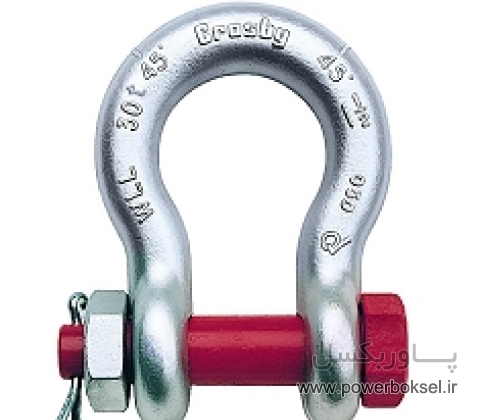

Shackles are one of the most important connections in lifting devices that have many applications for safe lifting in tow wire or chain lifting devices.Shackles in different shapes and tonnages are offered in the market, which according to the work and the position of the workplace as well as the dimensions, the desired volume of work,Are selected.The Shackles makes it easier and safer to connect the tow wire or chain to other connections such as Industrialhooks, steel chain and tow connectors, earrings, etc.The word Shackles in the dictionary means shackles, chains and restraints, and according to this, in various industries it is known as shackles.

Shackles are one of the most important connections in lifting devices that have many applications for safe lifting in tow wire or chain lifting devices.Shackles in different shapes and tonnages are offered in the market, which according to the work and the position of the workplace as well as the dimensions, the desired volume of work,Are selected.The Shackles makes it easier and safer to connect the tow wire or chain to other connections such as Industrialhooks, steel chain and tow connectors, earrings, etc.The word Shackles in the dictionary means shackles, chains and restraints, and according to this, in various industries it is known as shackles.

A Shackles is a portable connection ring used to connect various load-bearing equipment and components.

For example, a Shackles is used to connect tow ropes, chains, crane industrial hooks and other equipment to the load.

Shackles are generally made in two shapes: horseshoe (curved) or D-shaped.

Almost all types of jaws consist of a type of curved forged steel rod with two eyes and a pin.

Manganese metal is also used in the construction of the shackle.

In other words, the shackle is a kind of strong and curved connection that forms a closed loop.

Since the shackle has an important task in lifting joints, unlike its simple shape, it has a complex manufacturing process.

The body of the shackle is made of forged integrated steel without any welding.

The pin is made of forged and machined steel rods.

Then the heat treatment on the jaws is done by one of the following methods:

Heat to 50 ° C above the critical point of the steel and then cool in the open air.

Heat to 50 ° C above the critical point of the steel and then place in water or oil at 550 to 660 ° C.

According to BS standard, shackles that have been hardened and heat treated

In the arc of the job, code 04 or 06 is marked as a quality mark on it.

The factory is obliged to provide the buyer with a technical health certificate with the job.

All jobs that have been heat treated and hardened

They must be tested for Proof Test, which must be performed by an experienced inspector.

To prevent rust and corrosion, the forged steel is covered with a galvanized coating of zinc or cadmium.

The size of the jaws is determined by the diameter of their body.

Jacks are widely used in loading operations and must be carefully used and inspected.

According to the standard, the manufacturers of the job are obliged to permanently engrave the following items legibly on the body of the job:

1 - Manufacturer's name (its brand)

2 - Shoggle size

3 - Permitted capacity of the job (SWL)

In most jobs, the pin is screwed directly into the eye hole of the job.

It should be noted that non-screw pin jobs can usually withstand the lateral pressures of the load to lift the load vertically.

Occasionally there is a chip with screws and nuts

These jaws are used for places where the jig does not need to be opened and closed frequently

In other words, these jobs are used for long and permanent installations.

- 500x500 kopiëren.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)